-

Posts

142 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Classifieds

Posts posted by FricFrac

-

-

yup, it's happening.

$30 in so far lol

Definately interested. It's been done before but not well documented - keep us posted. PICS!

-

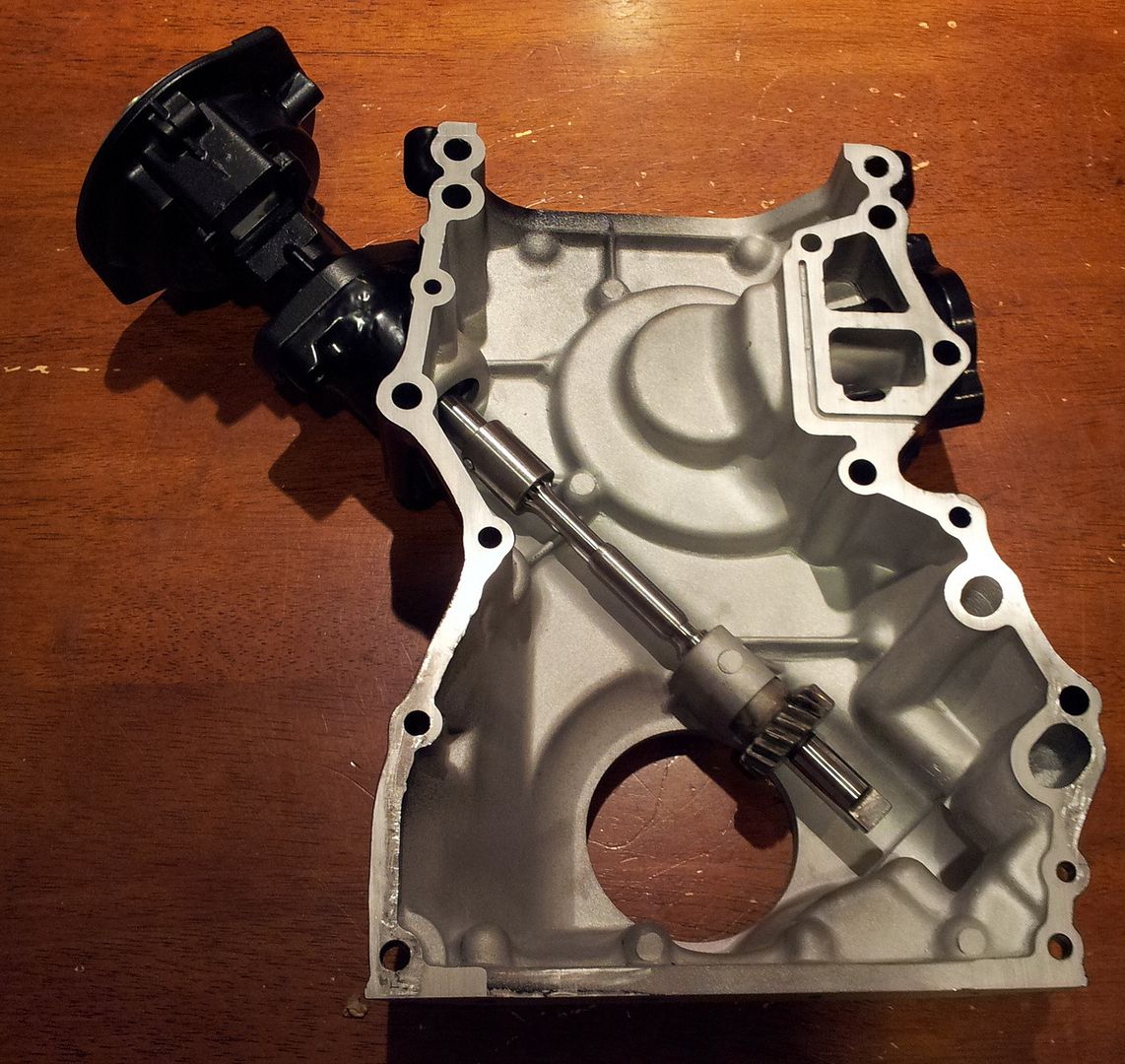

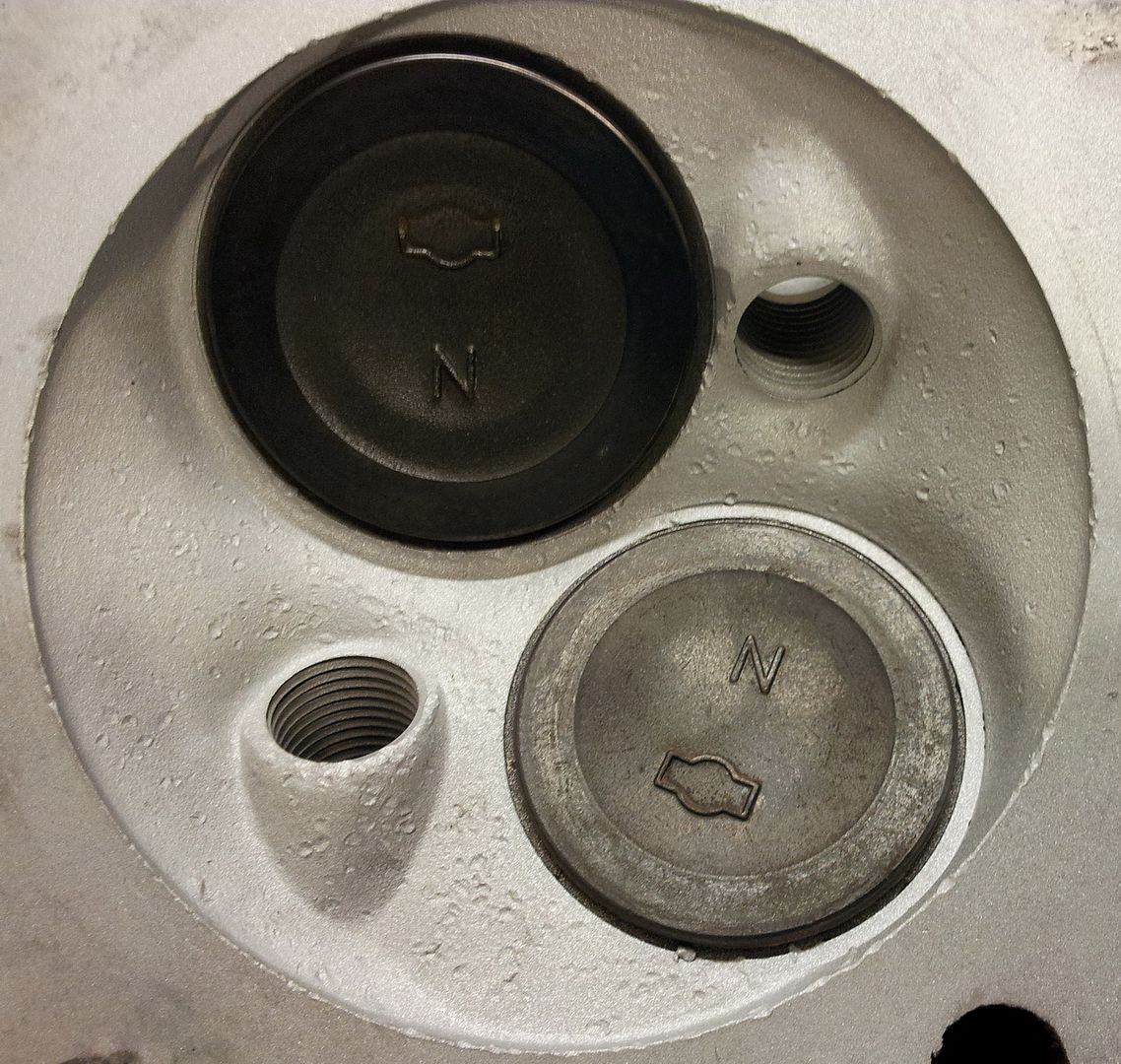

Z24i optical dizzy with a modified L28ET oil pump spindle - voila!

-

Didn't get a spindle with my Z24i dizzy so I had one "made up" from an L28ET (which is too long) with the optical dizzy (eg not an '81 with the CAS). Sleaved for a nice compression fit. The original stock dizzy spindle beside the modified one.

-

For my flat black '69 2dr 510....

-

4

4

-

-

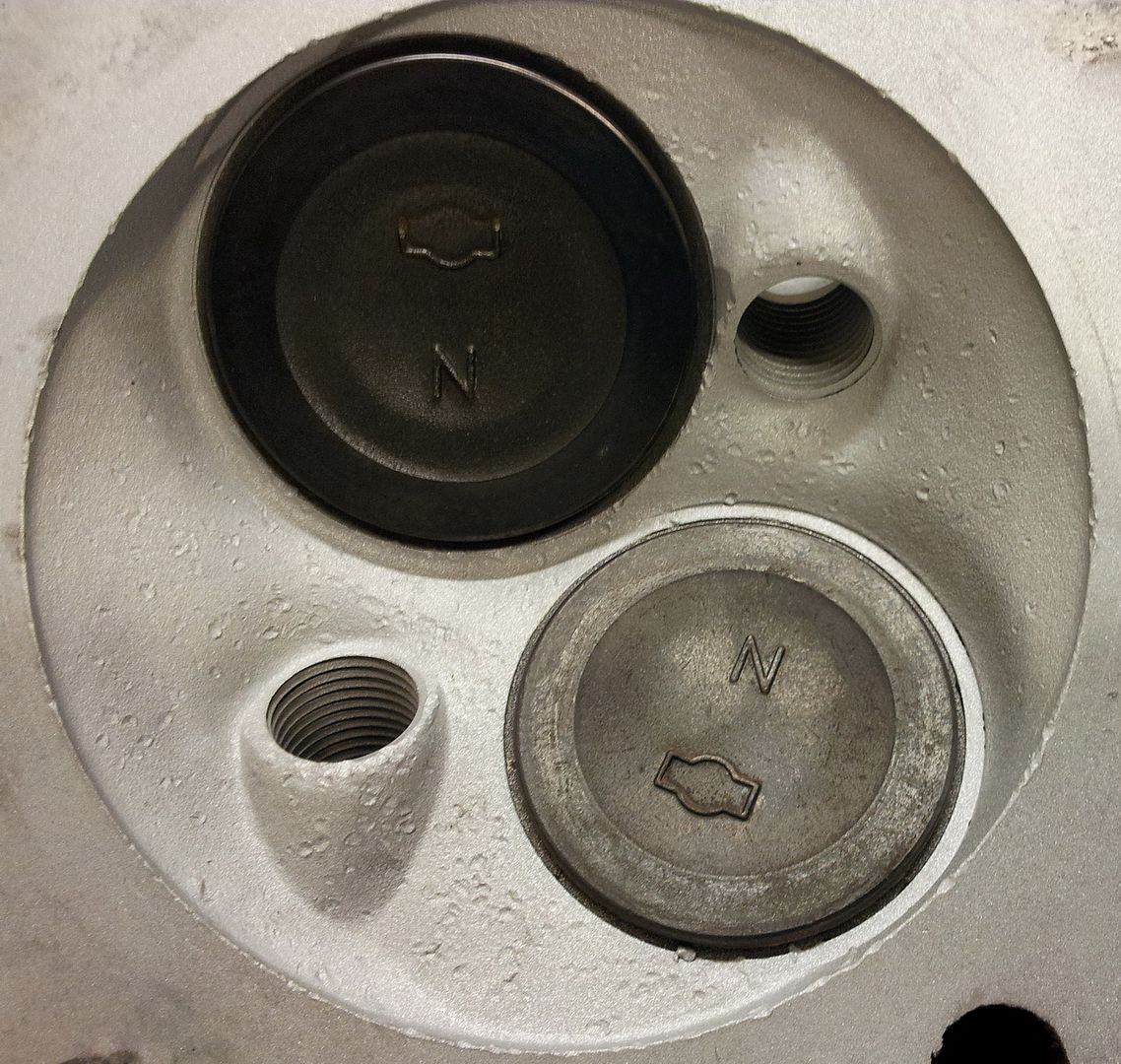

Sow's Ear:

Silk Purse:

-

-

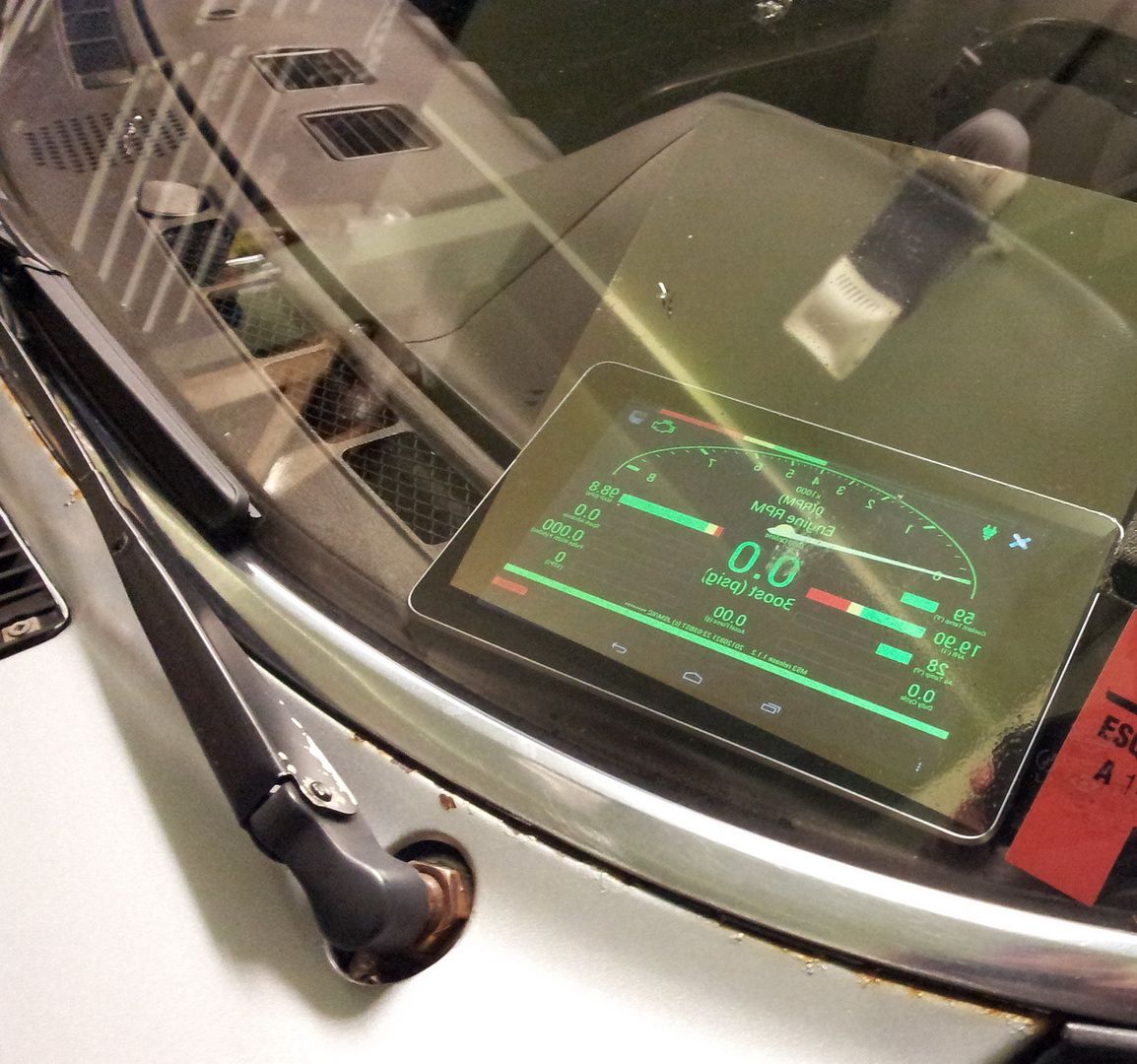

Jumping ahead here a bit but I was playing with the new Shadow Dash software for the Android to implement a HUD for the Mega Squirt 3 I'll be running in the car. Man this is slick!

PDA on the dash

Piece of reflective window tint and voila - HUD!

Of course pictures don't do it justice so a quick and dirty video of the HUD

-

1

1

-

-

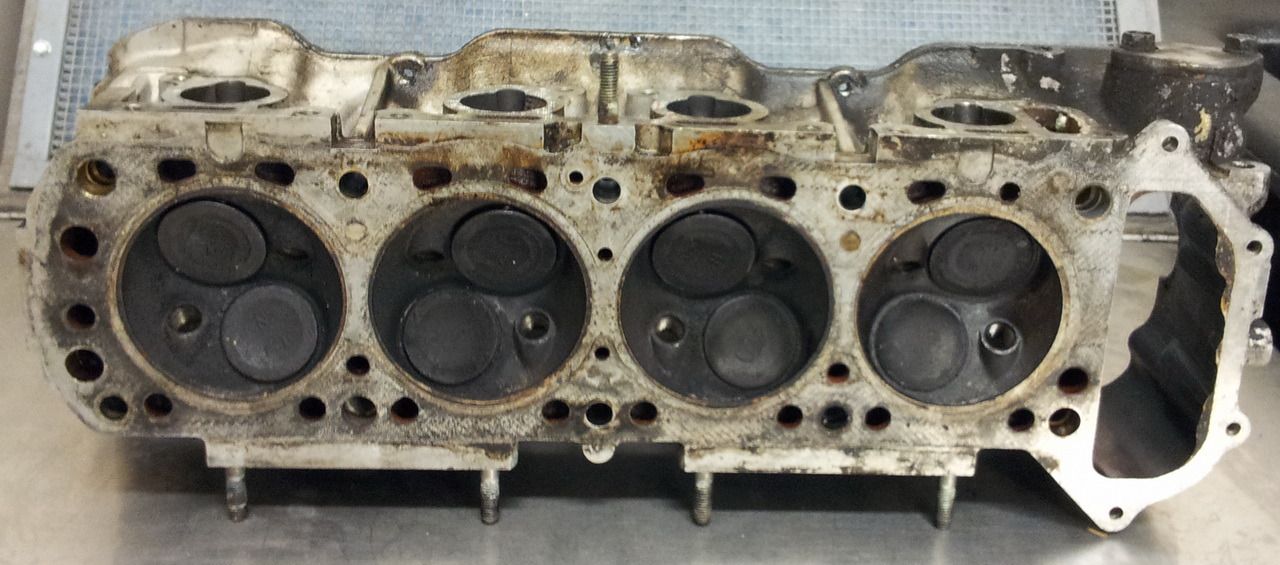

Took the engine apart so it's all sitting in bits on my buddy's garage on the bench. Took the head apart and started to give 'er some loving:

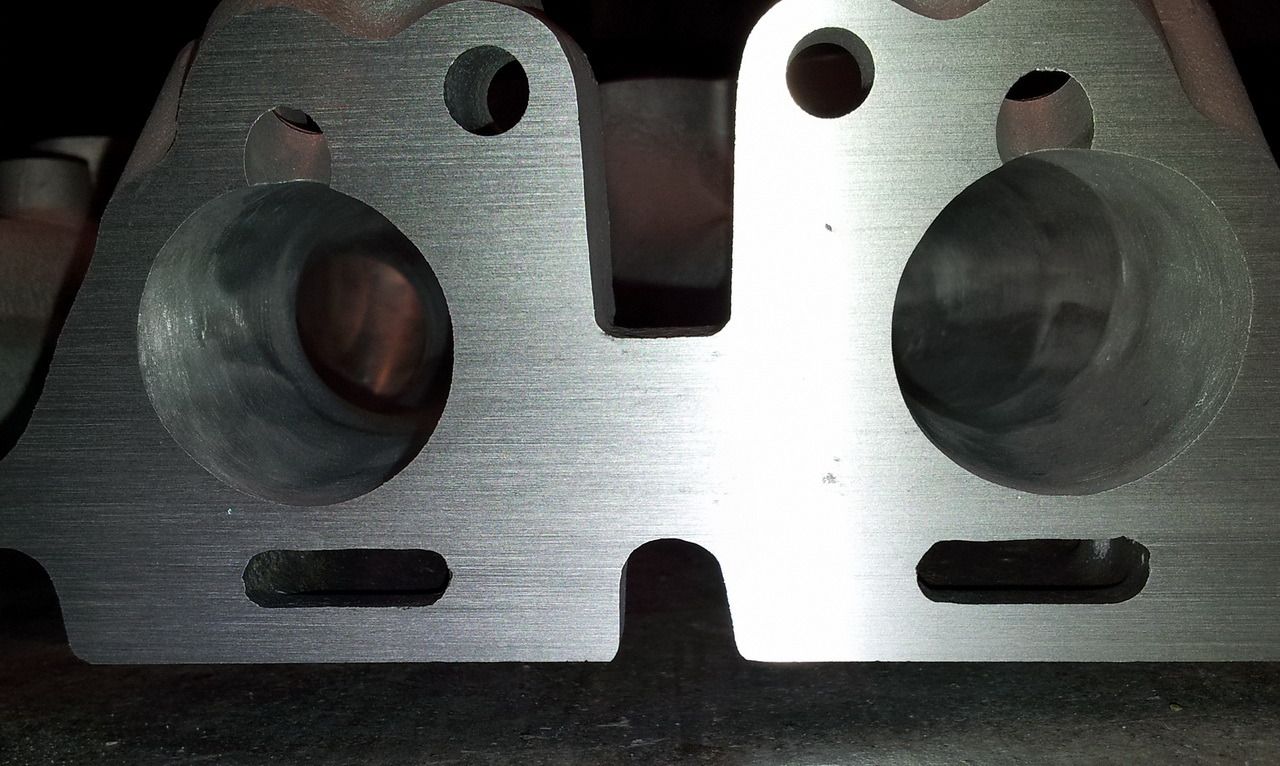

The gratuitous before picture of the carbon coated chamber:

After a good long cleaning:

After I cleaned the combustion chamber I saw quite a bit of damage. Looks like something bounced around in all the chambers. Of course the first one I started working on was the worst and I forgot to take before pictures but you get the idea from this one:

After some sweet loving she's starting to clean up. Still in the process of cleaning the chamber up but it looks like there is hope :) Tried to remove as little as possible but I'm not too worried about reducing the compression ratio from the small amount of material removed. Just trying to keep the chamber as clean and slick as possible to keep any hot spots to a minimum and thus prevent detonation. It will of course help with flow but reducing detonation is more important IMHO in this turbo application.

-

Nice :) More S130 love! The Rota's are the cat's ass for these cars... I'm running 17x9.5 on all four corners 235/255 and Yasin is braver than I running 255/275 and they look amazing!

-

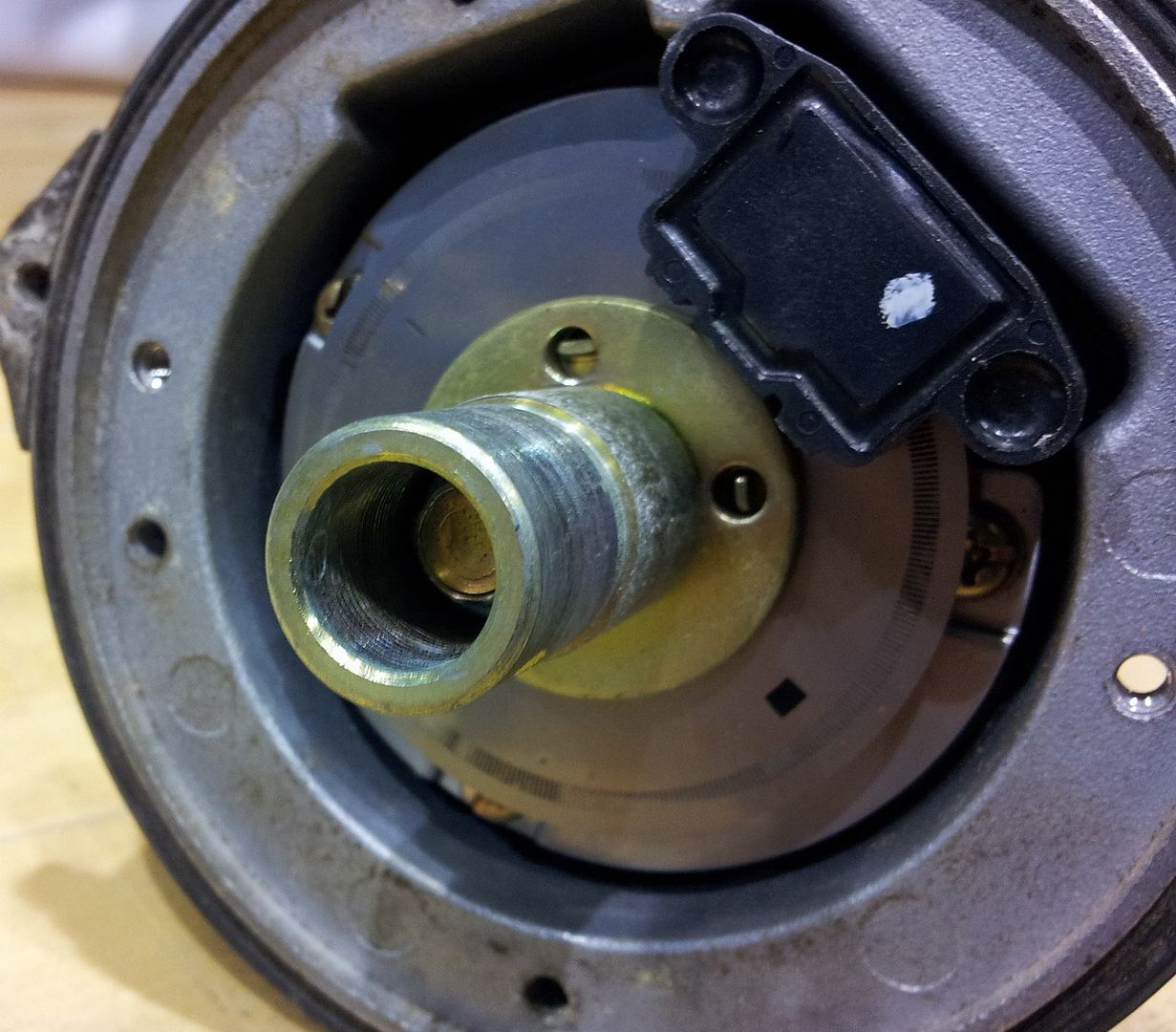

And here's my dizzy from a Z24i with the optical encoder wheel. I might be able to use the wheel as is since it has a larger slot for TDC. MS3 firmware 1.1.2 supports the Nissan CAS so we'll see if that works. If not I've got a 24-1-1 50mm optical encoder wheel we cut on the water jet that should work instead. I cut it for the L28ET but it's the same size conveniently ;)

Has the same 10 spline count as the L28ET oil pump shaft which should work in the Z22

Stock 50mm optical encoder wheel. Same size as the L28ET and VG30E dizzy. Different in that it has a larger slot for TDC whereas the L28ET are all equal size (and six instead of four slots on the second ring)

The pigtail looks like it goes right into the dizzy but it's just a cover plate that holds the more common rectangular four pin connector - same as the L28ET dizzy. Nice as this makes it easier to interface to

-

Ha ha great minds think alike....

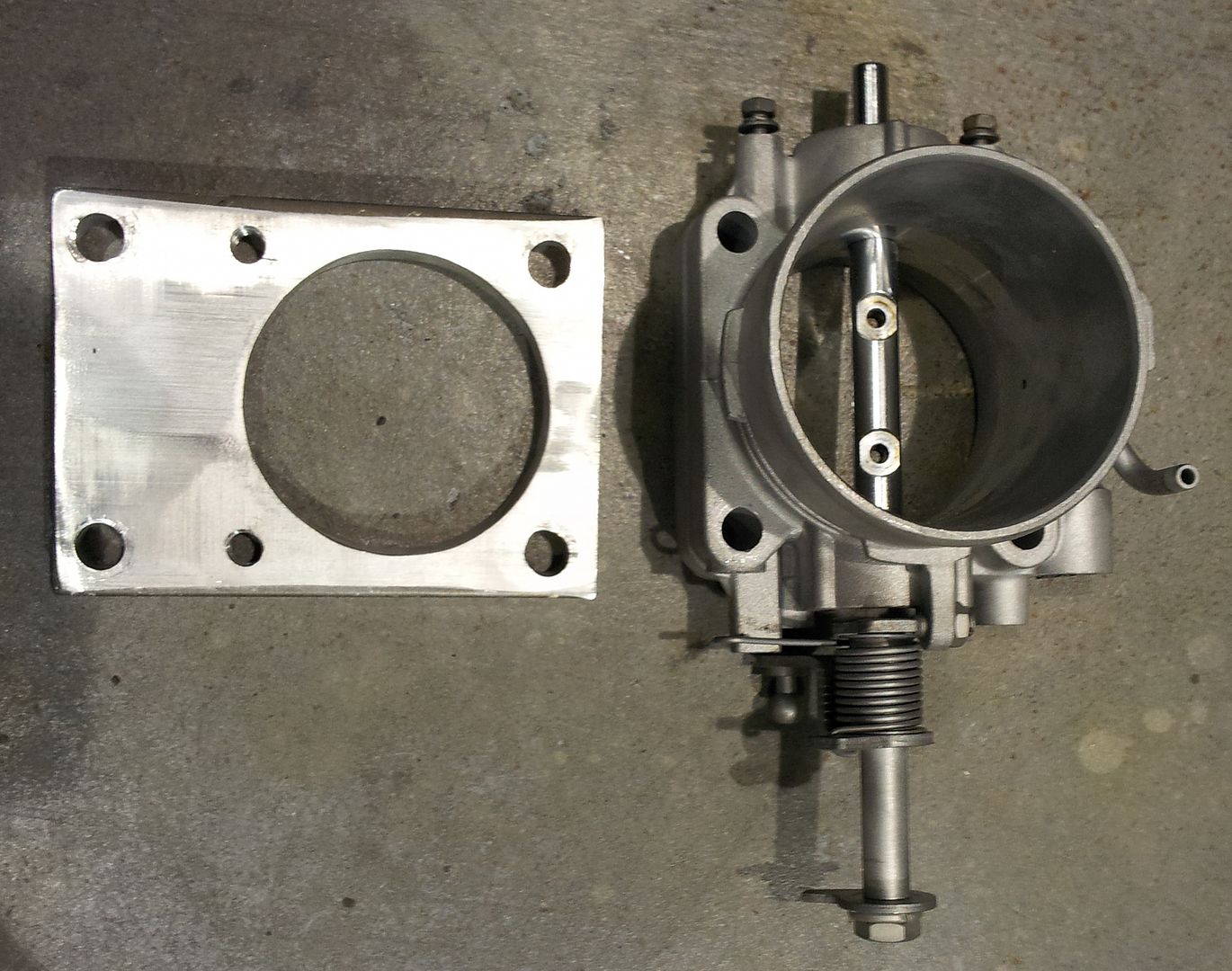

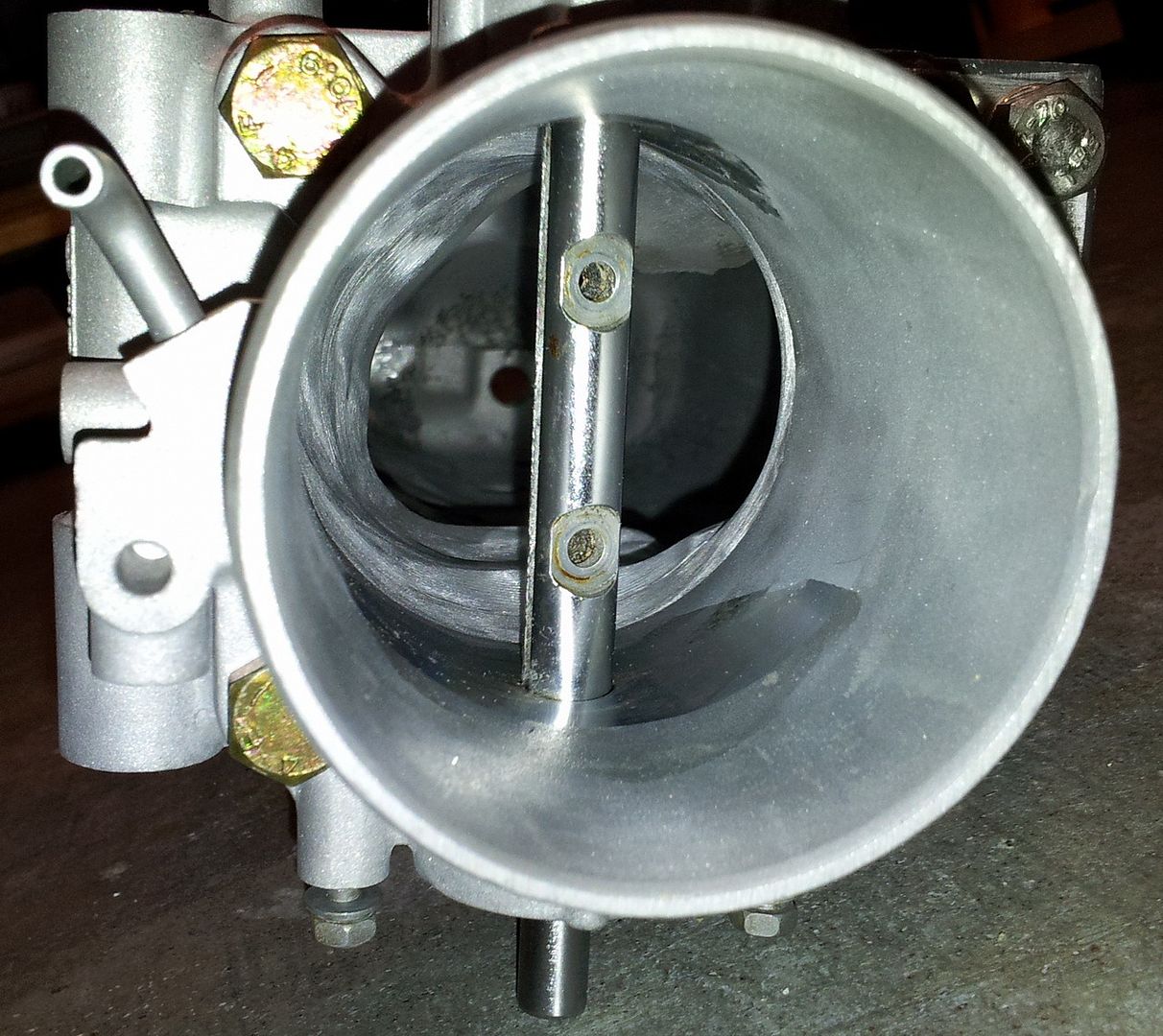

240sx and 200sx TBs.

My intake is the earlier type

Matt HRH has the other one.

Mine was the dual butterfly valve 200SX thus the tear drop shape inlet....

-

Of course I haven't even had her towed home and I'm researching engine swaps. You know the usual KA24, SR20, VG30E and ET, etc... I'm trying to get 'er running in the drive way and I'm not having a lot of luck. I rebuilt the carb not knowing what kind of shape it's in. Getting better. Find a bunch of vacuum leaks. Replace the weak coil. I'm an Electronics Eng so I pull the stock harness out of the engine bay and give 'er a rebuild. I've got all the connectors for the 240Z, etc so I was already good to go there - add some new ground wires, etc. The whole time I'm fighting with this I'm thinking how much easier it would be if I was running Mega Squirt like I just built for the 280ZXT. That's when I start thinking about building an L16 turbo with EFI (MS3). I start researching about how to make this happen. I think it would be a fun little engine and I don't need an insane build - I've got other cars that make lots of power and the L16 turbo is kinda unique as most people don't bother. I start researching EFI manifolds and figure I'm going to have to build my own. Then I start trying to figure out how I'm going to trigger the EFI. Looking into an L28ET dizzy, etc and I find out that the Z24i has an optical dizzy. It also has a hemi head with a good quench area - hmmm that's perfect for a turbo build. A friend of mine tells me he has a Z22 so I do some horse trading (thanks Greg!) and now I'm going down the Z22 EFI turbo road. She burns oil so now's the time for a rebuild. The tentative plans are a full gasket set, ITM hyperutectic pistons and rings (only $50 more than rings alone - seems like a no brainer), ARP head and rod bolts (good for a boosted engine and the NAPSZ seems to have an issue with the head bolts getting loose after time), and Cleavite crank and rod bearings. Once we get her cracked open we'll see if anything else needs doing but I'm trying to keep this fairly low cost. I picked up an extra oil pan (thanks Peter!) and oil pickup (thanks Hayden!) so I don't need to rip the L16 apart to build this thing.

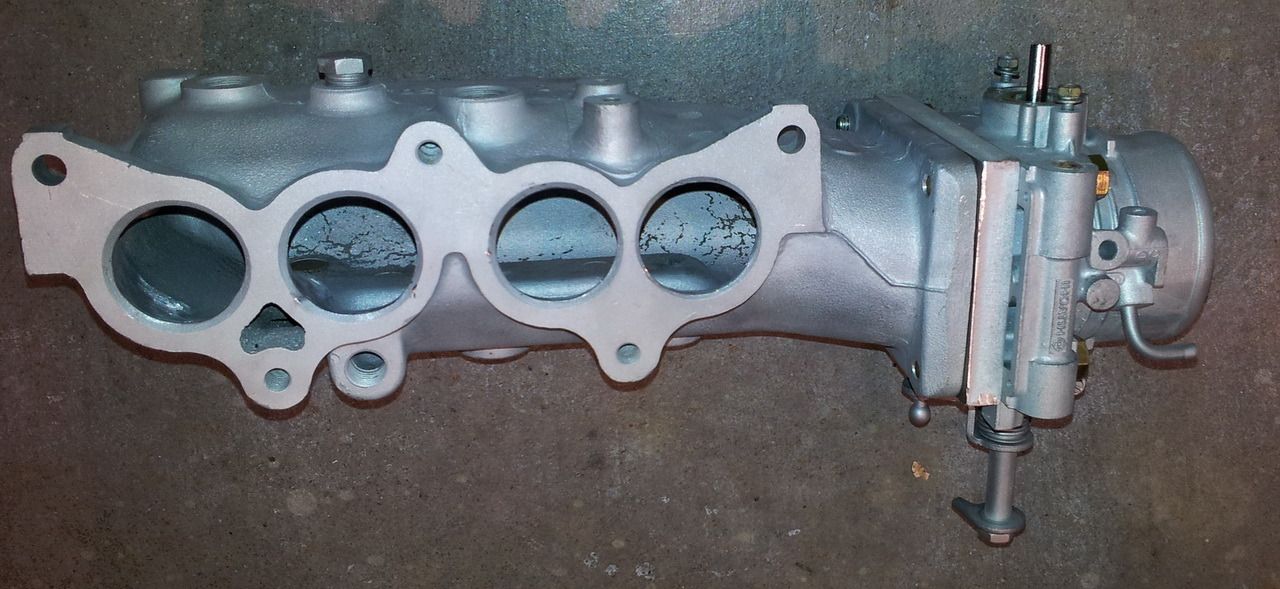

So the challenge of this beast is to get it into EFI land. I'm already part way there researching for the L16 EFI conversion. I need an EFI manifold from an early 200SX (Z20) and an optical dizzy from the later Z24i Hardbody. DatsunMike as always has been a pile of help. Posted tons of picks and pointed me in the right direction. Found a dizzy from a Z24i (thanks Sealick!) and while I was looking at a 280ZX for a good friend of mine I look down in the dirt literally and there lies a 200SX intake plenum and runners - the last piece of the puzzle (thanks Robert!)

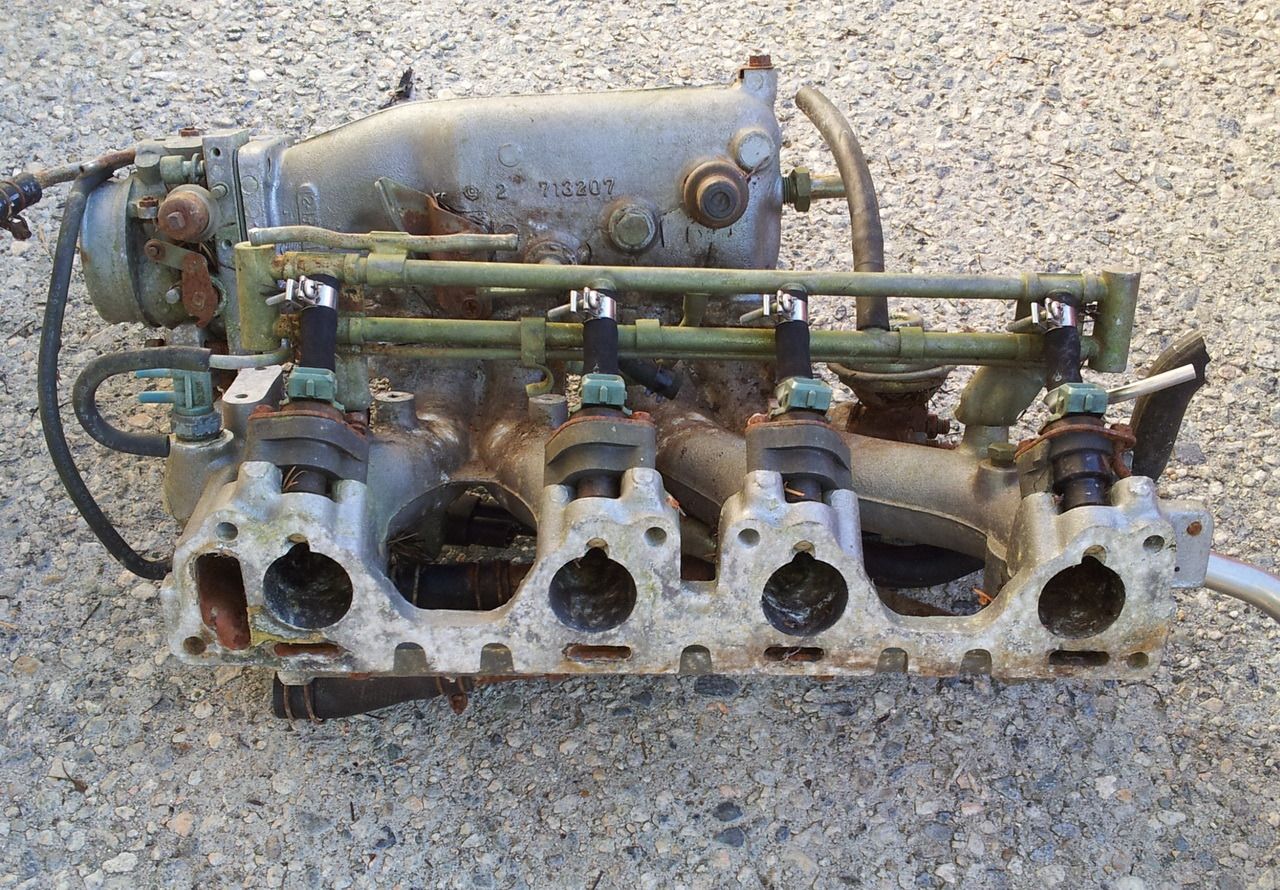

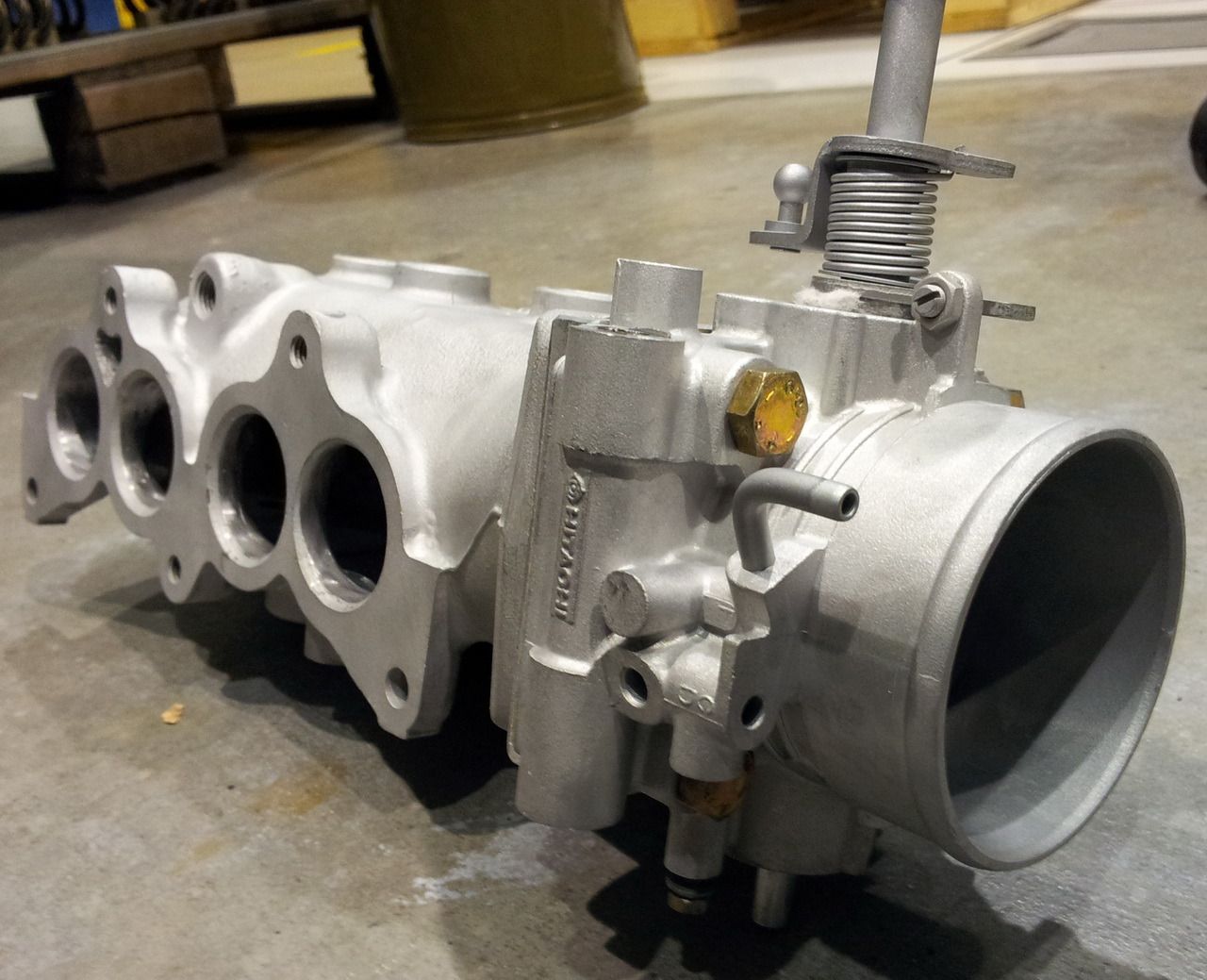

So here's the plenum and runners before the masaging begins (minus 12lbs of pine needles)

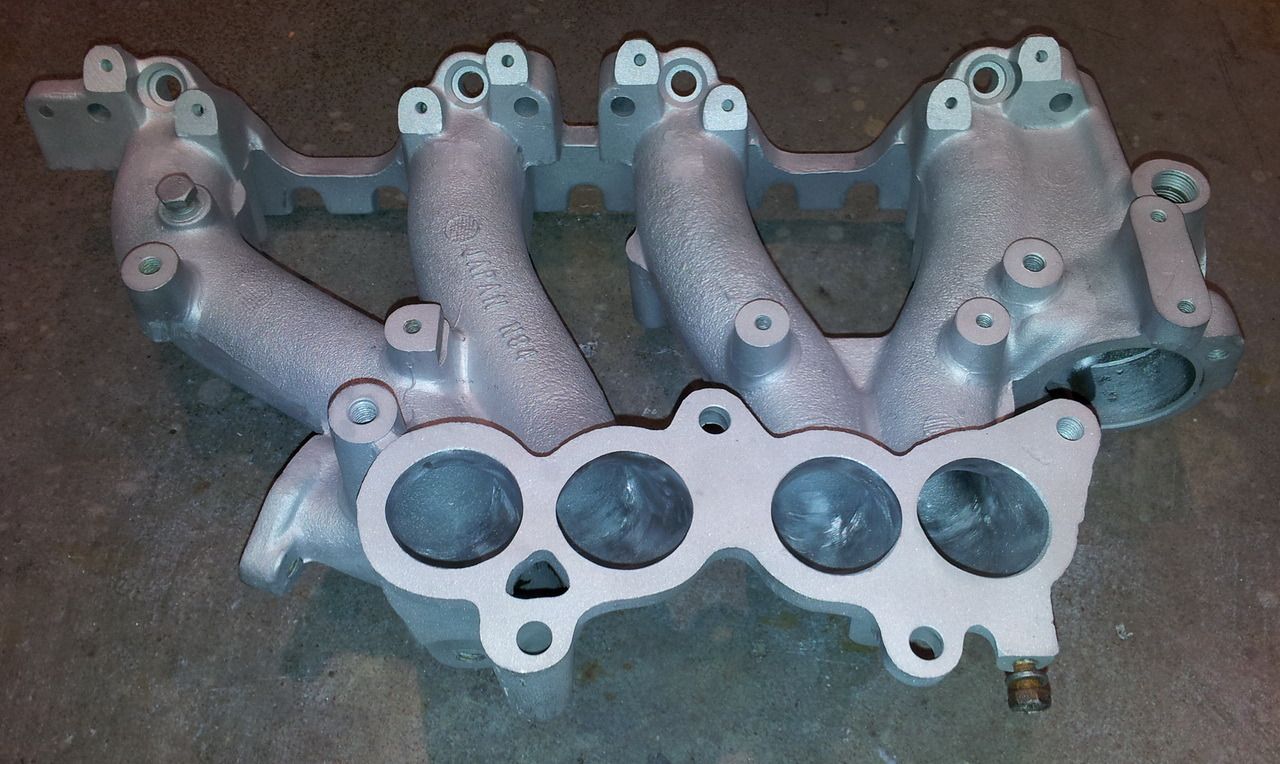

Intake runners bead blasted, ported and polished

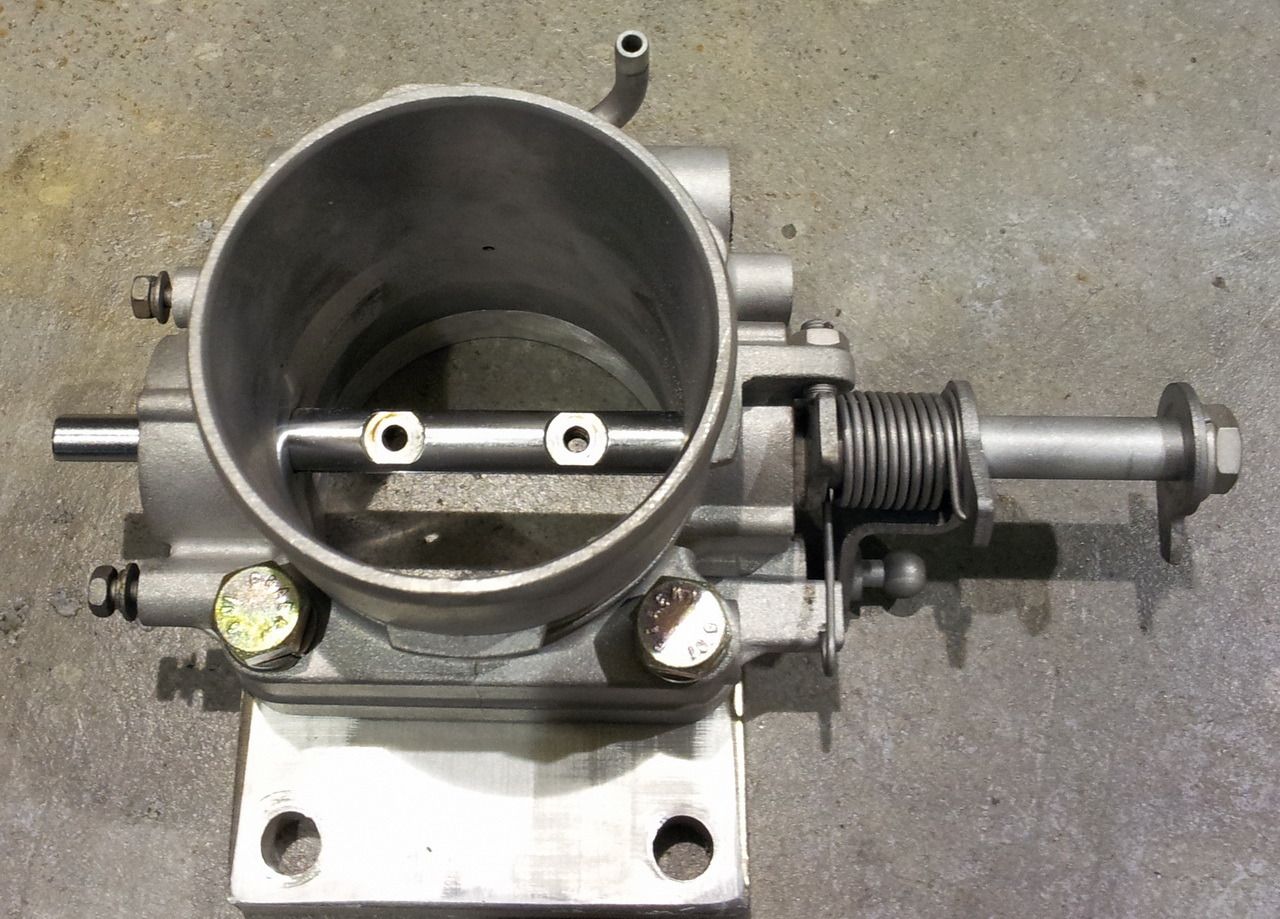

Intake plenum ported to accept a 240SX 60mm throttle body. Might be a little overkill so I may have to go to a 280ZX 48mm TB for better throttle response. We'll have to see how it works out.

Intake plenum with 240SX TB and an adapter plate made of 1/2" aluminum. Two screw holes are tapped into the plate to mount the TB and the other two line up with the stock mounts. Third set of holes mounts to the stock location below the TB. Cut the water inlet/outlet off the TB to reduce plumbing.

Plenum and TB test fitted. TB adapter is port matched to the plenum

-

Well I guess I should start a build thread. Like everyone and their dog here long time 510 fan always wanted one but being a Z car guy first and foremost the 510 kinda went to the back burner. Kept an eye out and missed a few but most of the stuff around here is rotten and goes for a fortune. Long story short a guy I knew had one about three years ago. It was a project he picked up from a kid. Put the car back together, added bubble flairs and painted it flat black. Found a rebuilt L16 and dropped it in. Shortly thereafter he found his dream car - '60's Impala which he proceeded to dump huge piles of cash into to build his dream car. I told him if he was ever going to sell the 510 to let me know. Three years later I get a message on my phone from our local classified adds which pops up any time anything Datsun is listed. 95% of the time it's either wheels that fit a Datsun, books with Datsun in a picture on the 59th page or some rotten piece of junk. Anyhow this time it turns out to be this 510 and it sure looked like the guy's car that I talked to years ago so I call the number right away. He answers the phone and I ask him if this is so and so and it turns out it's the guy. He says he just posted the ad less than five minutes ago. Anyhow I ended up buying it and so it begins....

After she arrives at home with some of her stable mates:

Missing the rear cover so I covered her shame with a piece of sheet metal till I can get around to fitting something properly.

-

1

1

-

-

I needed some nice bolts for the Strut Tower bar so I Googled “12 point 3/8” x 3” flange bolt.” Came up with a company named Allen Fasteners. Everything looked legit and the site allowed me to buy bolts one at a time. The pricing was kind of high but better than having to buy 5, 10 or 20 at a time.

So I ordered two 3/8-24x3” 12 Point Flange bolts and matching 12pt Stainless Nuts. Cost me around $18.

I receive the hardware and attempt to spin the nut onto the bolt. Well, it would not go on smoothly. So I got a couple of wrenches and started to chase the threads with the Nut.

Well, the damn nut galls and gets stuck onto the bolt. It was not cross threaded or anything. WTF? I tried the other bolt and nut, it would not go on smoothly either but I was not about to make the same mistake.

So I email the company and after 2 days don’t get a response.

I then decide to call them. A guy names Allen gets on the phone. Guess it’s his company.

Well, I explain the problem to him and he asks me if I used anti seize on the nut first.

I told him no, why? I was just dry fitting the nut without any torque. He told me I always need to use anti seize. I was like huh? I shouldn’t have to use it to just spin a nut onto a bolt. Besides, I have hundreds of bolts on my car that don’t need anti seize. Also, anti seize is for applications where there is heat and cooling cycles and possible galling when torqued.

I started to say I wanted ARP nuts and bolts instead cause they are made to a standard but he cuts me off mid sentence with a huff and says “Fuck this shit, just send them back and I will credit your back the money." I then started to say all I wanted is an exchange but he cuts me off again saying, “I'll say it one more time man, send 'em back, you'll get your money and that's the end of it.”

I was like Whaaat the hell. That escalated way too fast.

So I apologized for any miss understanding and tried another time to calmly explain what I wanted and he fuckin’ cuts me off again saying, “Your never going to be happy, so just fucking send back the bolts and that’s it. I’ll credit you your fucking money and that will be the end of it.”

WTF??!!

At that point I just said, “Thanks for the stellar Customer Service, Have a good Day.” and hung up.

I sent that shit out ½ hour later!

So just say No to Allen Fasteners or call Mr. Ballistic just to fuck with him!!! 19092238347…. Hahaha

Anti Sieze is to prevent corrosion and allow the fastener to be removed when exposed to the elements. There are other lubricants for beding in nuts, etc and anti sieze isn't one of them. Thanks for the heads up on Allan and his wreaked nuts.

Wicked build btw :)

-

1

1

-

-

Makes me wonder what a 610 would look like with a 510 grill ;)

-

2

2

-

-

Hmmm lots of power but cheap. As a rule they are mutually exclusive but there are the odd exception.

.........

Have a girlfriend?

If not careful they can get pregnant and a half finished project gets sold or sits at your parents for 5 years.

Lol this one so often get's overlooked in the free advice column but it's so true. RIP to my wrenching buddy and his new girlfriend lol

-

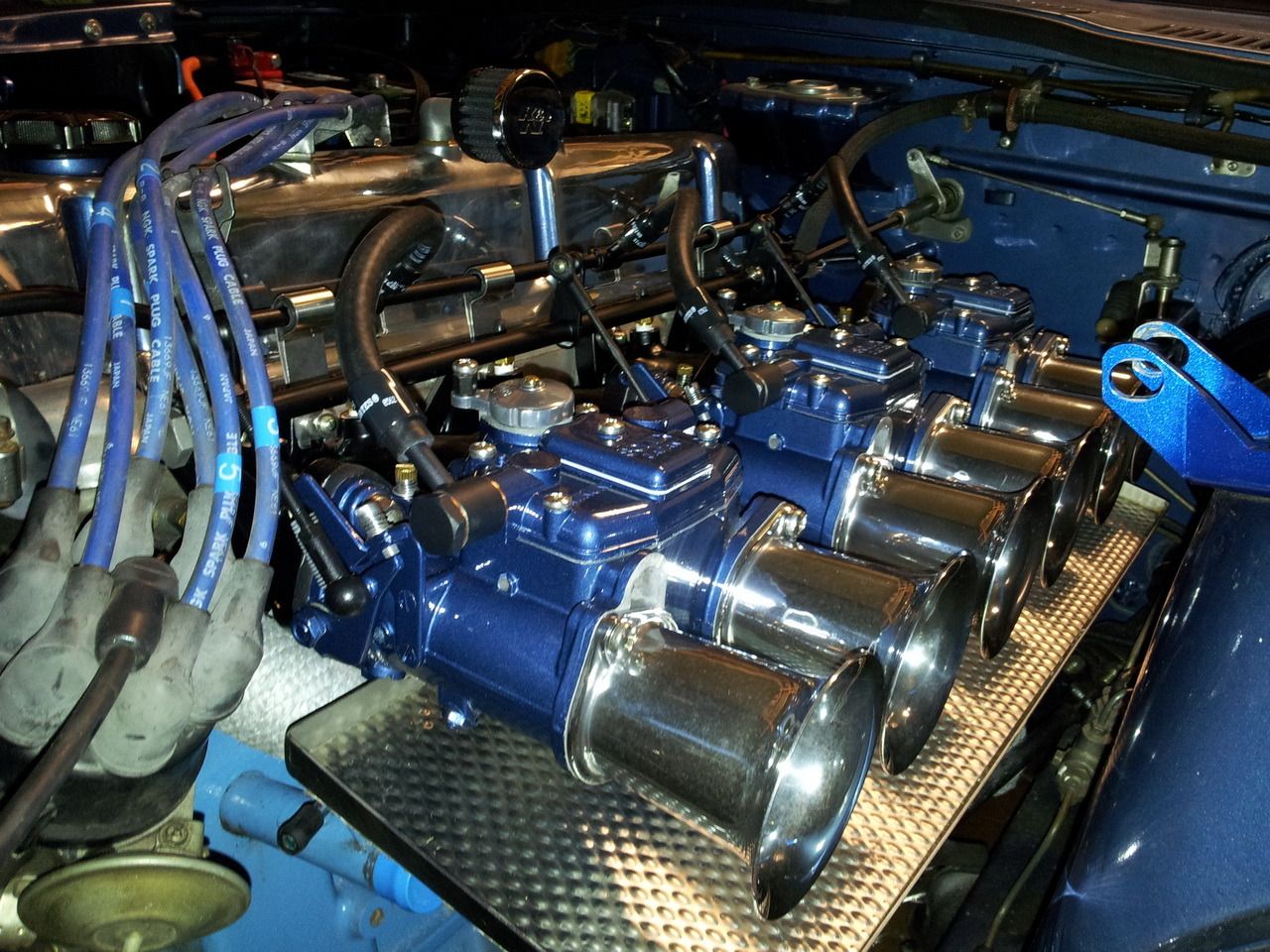

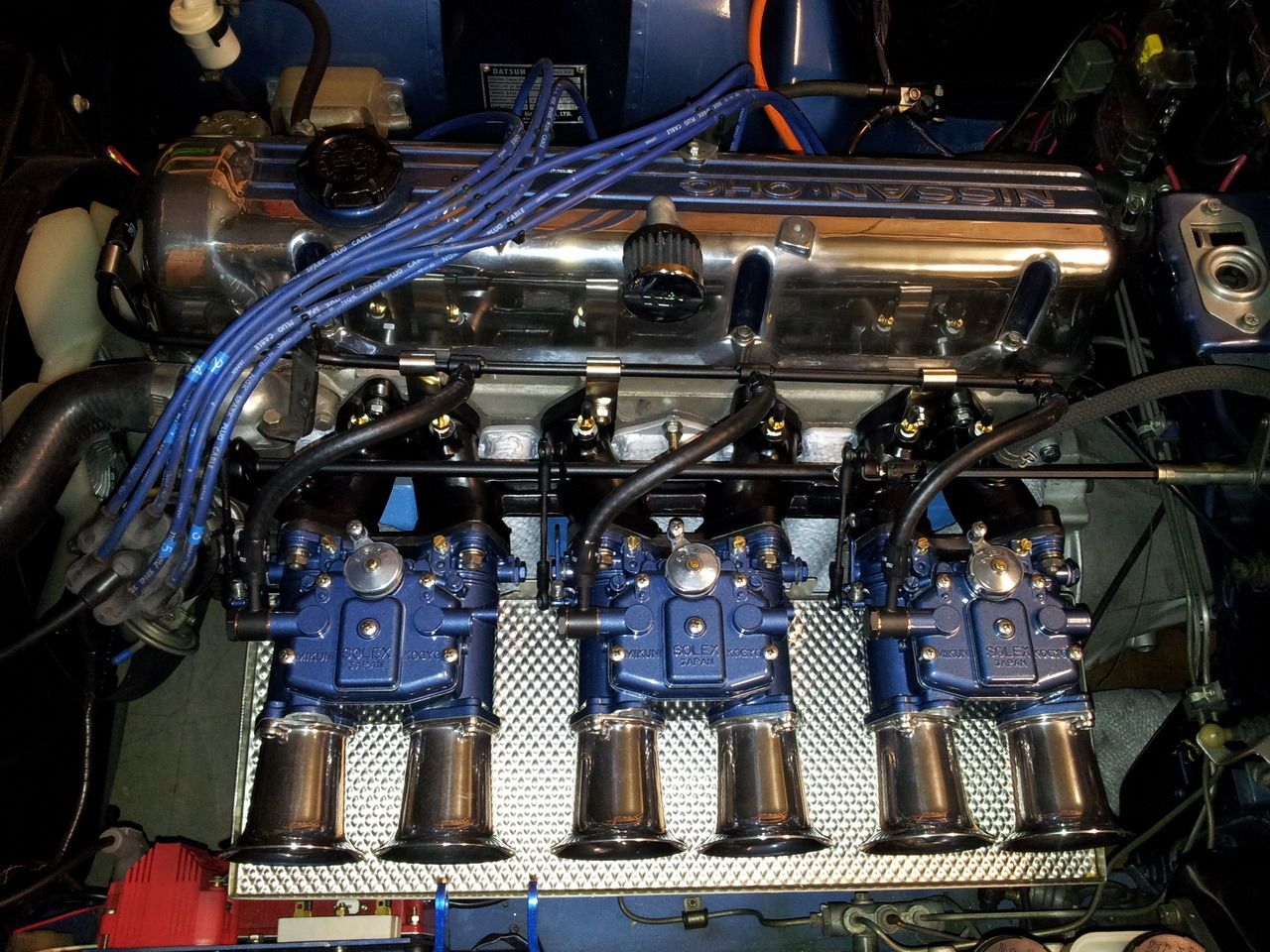

Nice looking set up. I'm always eh with painting dcoes but that looks pretty good.

It's OK - these are Mikuni's ;P They looked wretched before...

-

Summer love for the 240Z. Well it was suppose to be done for the spring but it was the middle of the summer before I finished the "tidy up".

- Rebuilt and painted the carbs

- Rebuilt the headers (yea what a mess - patched, grapes hanging inside. If I knew what a mess they were before I started I would have bought new headers. I'm glad I was able to keep them as they are the original old school headers the car had in '72.), POR 20, wrapped and sealed, added O2 bung for WB02

- Ported and polished intake runners, added bosses for individual vacuum ports for adjusting carbs, etc.

- Powder coated runners, fuel rail, etc

- New stainless brackets for fuel rail

- New fuel line and heat shrink clamps (cool clamps just wish they didn't have white printing on them)

- Modified throttle linkage with RC 1/8th scale truck parts - u-joints and adjustable rods.

I have since upgraded to the 280ZX dizzy and still need to do the starter (choke) cable and stainless piping for the breather/catch can.

-

2

2

-

-

Oil is a hotly debated topic and when it boils down to it the most important thing about oil is regular oil AND filter changes (who in the world would try to reuse a $5-10 filter...)

You can spend hours or even days reading a lot of insiteful info about oil at bobistheoilguy.com where chemical engineers, etc hang out and debate. Lots of lab testing results, VOC, etc.

Personally I like the lab results for the Pennzoil Platinum. I run 5W30 in ALL my cars - from the '69 510 to my '09 370Z and I use WIX filters.

A few points about oil that get overlooked but are important to know.

Oil pressure - the important thing about oil in your engine is that it provides a protective barrier between two metal parts. In order to provide that barrier it needs to get to where it's going, hang out for a while and leave when the new oil arrives. To do that you need oil FLOW not pressure. Of course it's pressure that keeps the flow going but you can have plenty of pressure and no flow. For some reason people think high oil pressure is improving your oiling system. If that was the case then grease should give you some pretty good high pressures.... You should be more concerned about keeping your oil at the temperature it was designed to run at - about 180F. If you are using an oil cooler then you'll want to use a thermal plate to keep the oil from going to the cooler until it reaches 180F.

Start up - the majority of the wear in your engine particularly in the valve train is when you don't have oil flowing on the initial start up. There is oil on everything even if it's been sitting for years otherwise wear would be extreme. I will agree that ZDDP would help for start up to protect from wear but there are other modern protectants like Nissan's DLC that do the same thing. Personally I think that running the lowest first number (eg 0W30 where the first number is 0, 5W30, etc) which is the viscosity of the oil at initial start and the oil that is already there provides enough protection on start up. I'd rather have oil up in the valve train quicker with 0W or 5W than relying on ZDDP to protect until the 10W or 20W gets up there. I've never worn out a cam shaft, etc on any L series engines I've had in the last 20 years and who knows what the previous owner before me were doing to it. Almost every L series I've taken the head off of still has the cross hatching in the cylinder walls. These are tough engines and they wear well.

Synthetic - There are some misconceptions about synthetic oil when used on old cars. People will say when they change over to synthetic the seals started to weap and leak oil. This can be true but the problem isn't the oil. I'll explain why. Oil is just a bunch of hydrocarbon chains of a certain length to make it a liquid at room temperature (ok that's the simple explaination). As hydro carbon chains get longer they tend to become more solid (grease, wax, plastics, etc). Dinosaur oil tends to be a mixture of chains whereas synthetic is all one length chain (again simplifying). Lets just make up some numbers for illustration purposes. Let's say 10W30 dinosaur oil is made of a mixture of 10, 12 and 14 carbon atoms. Synthetic 10W30 is all the same - 12 carbon atoms long. That blend in the dino oil gives the 10W30 properties that the all-the-same 12 chain in the synthetic does to give it the 10W30 properties. So lets go back to the leaky seals. When your seal are old and should be replaced those 14 atom long chains will provide a barrier for the 10 and 12 chain molecules that would leak past. When you run synthetic they are all 12 atom chains with no 14 atom chains to keep them in. The issue is that the seals are old and the blend of oil dino keeps it from weaping. Replace the seals if your engine leaks with synthetic oil - the seals are the problem not the oil.

Here is why you want to use synthetic. It's more consistant and more rugged. I'm simplifying things when I say dino oil has 10, 12 and 14 atom chains. It actually has a whole blend of different stuff that will be different from batch to batch. They make sure it meets the 10W30 spec but it's just viscosity at certain temperatures. Synthetic is more tightly controlled because they are using a known chain of atoms with a specific property. It's more resistant to breaking down under presure and heat than dino oil's mish mash of molecules. I'd rather have all 12 chain molecules between my cam and rockers than some 4, 7, 10 and 14s and who knows what. Synthetics are less likely to break down under heat and presure than dino oil which is why in a turbo application you want to be running synthetic. I'm not sure what the story with Royal Purple and turbos is but I suspect it's and additive (anti foaming, detergent, etc) that breaks down under high presure/heat.

Oil has come a LONG way in the last 20 or 30 years. Detergents are a big one. Sludge was normal but how often in modern engines do you see sludge? No sludge is a good thing IMHO. I'm not an expert but I don't think sludge has very good lubricating properties ;P

Oh yea another thing to remember about synthetic is because it does lubricate so well in comparison to dino oil you don't want to use it when you rebuild an engine because it can prevent your rings from seating properly. Dino oil for break in!

-

Maybe it was removed. It should have it.

I know I was puzzled as well. I'd post a pic but Photobucket is misbehaving. I posted a pic in the 510 realm thread.

-

Cool thanks for the pics - that is the same size as the 280ZX optical wheel (as opposed to the 240SX). I've got a prototype optical wheel cut on the water jet that will drop right in.

Is this a four or eight wire cap that goes with the dizzy?

-

03 '88 to 08 '89 Hardbody or Pathfinder Z24i.

The late '80's Hardbody I found had no CAS in the dizzy but it was throttle body injection. It was the four plug version.

-

Here it is...

Zero play in shaft...would clean up as new

Pretty sure it's the Z24i dizzy.....Mike could probably confirm PN numbers

D4P84 04 B8803

22100 07G01

Cool - have the oil pump shaft for it as well? Is it running the splined coupler? Pics of the plug for the CAS? Pics of the optical wheel? Optical wheel diameter?

-

I might have one....will go have a look

You are going to 'document' this Mega Squirt NAPS Z2.2 build/conversion???..... :D

This is going in your 510?

I'll photo doc it as I go. I've got the misc stripped off the block right now getting ready to rebuild the engine. Yes - it's going into the 510 :) Wanted to do something a little different without a lot of modding to get it in. I think the NAPS Z head will be good for a boosted application. It will be interesting to see if it responds to water/methanol like the L series does.

Anyone have a timing curve for a Z22?

1969 Datsun 510 2Dr Z22 turbo EFI build

in Project Datto

Posted

Yea I read tons and I've always wanted to build but never had the time or means until now (well a little lacking in the time department still lol). Hoping to contribute along the way. It's an uncommon build but I'm hoping it turns out to be another worth while option for a fairly easy 510 peformance engine swap.